In any given process or system, multiple entities—be it individuals, groups, or even machines—play a task. Traceability ensures that every step taken or decision made is documented. This signifies that if something goes wrong or if there’s a need to know a specific determination, it’s simple to establish who or what was involved https://www.globalcloudteam.com/. This cultivates a tradition of duty the place each entity is conscious of that their actions are traceable and, in consequence, they’re extra likely to act with due diligence. It ensures not solely that every requirement has corresponding check cases but in addition that each test case is linked back to the originating requirements.

The Reason Why The Automated Optimization Of Project Portfolios Won’t Ever Work

Uniform processes and procedures across the board make sure that traceability is maintained constantly, no matter who is dealing with a product or process. In its easiest vertical traceability form, traceability refers to the ability to trace the history, software, or location of an entity by the use of recorded identifications. It’s like a breadcrumb trail that lets you retrace your steps back to the beginning point. If you need to unearth potential dangers, you may do a failure modes and effects evaluation (FMEA).

Listed Right Here Are Some Key Elements Of Supplier Mapping:

This section covers linking requirements as much as the source from which they sprang, a rationale for his or her identification, and necessities for different entities with which they are associated. In addition, as proven in Figure 2.4, we may also be thinking about longitudinal traceability that establishes linkage between a requirement, its design options, and verification info. Another sort of traceability of value is traceability to the modeling supply from which the requirement was derived, or lateral traceability. We may even discuss internal relevant documents traceability into the specification invoking requirements loosely linked to vertical traceability. For example, allow us to accept that we’ve a practical analysis database that features a record for each perform illustrated on the practical move diagrams.

Obtain Trade Updates In Your Mailbox!

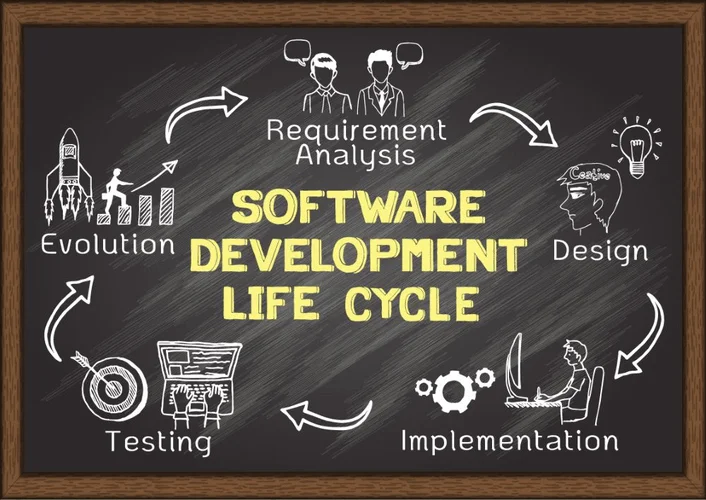

It includes the seize of low-level requirements which may be particular to the design and implementation and have no impact on the useful standards of the system. When the RTM turns into the center of the development course of it impacts on all levels of design from high-level necessities via to target-based deployment. Where an application is safety crucial each tier is prone to be carried out in full, however as quickly as once more a pragmatic interpretation of the principles may be applied to any project. Traceability links artifacts — requirements, supply code, exams, and issues — throughout the event lifecycle. This ensures that teams will have the ability to meet high quality standards, produce secure merchandise, and keep aggressive. Before your group commits to plunging, it had finest have an efficient means for tracing requirements impacts provided by an efficient computerized traceability matrix.

Tips On How To Create A Traceability Matrix

Another factor that has increased recalls is the improved capabilities of well being investigators and epidemiologists to correctly attribute pathogens to a single supply. National or regional data sharing methods (such as PulseNet) permit investigators to precisely match pulse subject gel electrophoresis patterns and whole genome sequencing data. With this data, investigators can determine if a pathogen discovered to be the source of a foodborne illness in a single space matches pathogens found in other diseases in different areas. Other data systems for sharing and tracking foodborne illness embody the Rapid Alert System for Food and Feed within the EU and the Food Alert System in the UK. By conducting food historical past interviews with the affected people, investigators can set up common food sources, ultimately figuring out a single source or ingredient responsible for the outbreak. The integrated administration system idea expands this traceability downward from the SOW to an integrated grasp plan (IMP) that tells how the contractor will handle and accomplish the work defined in the SOW.

The Way To Create Tm (traceability Matrix)?

This might signal that the requirement was not decomposed appropriately and might need been skipped. Horizontal traceability focuses on establishing relationships between artifacts inside the identical development part. For instance, it may contain linking test circumstances to one another based on shared take a look at goals or dependencies. Traceability is the flexibility to trace a product’s origin, motion, and history. It’s an important device for companies to trace the origin of uncooked materials, manufacturing processes, and distribution paths. Vertical traceability identifies the origin of items and follows these identical items as they travel through the hierarchy of the work breakdown construction to the project groups and finally to the shopper.

A Software Testing Traceability Matrix is a elementary device for managing and monitoring the testing process in software program growth projects. By establishing clear correlations between necessities, test instances, and different artifacts, an STM enhances transparency, facilitates impact analysis, and ensures comprehensive check coverage. Understanding the several varieties of traceability matrices—forward, backward, bidirectional, vertical, and horizontal—empowers teams to tailor their testing approach in accordance with project necessities and goals.

How A Lot Are You Willing To Waste In Fixing Your Project’s Performance Puzzle?

- Traceability can be used for decision-making all through product growth.

- Given a failure to hint, we might then inquire why that situation exists.

- And it’s important to have the ability to hint from one merchandise to the next and back again.

- A document of the traceability between requirements for system elements affords customer and company administration an opportunity to watch development group progress by offering insights into potential gold plating.

This sort of tracing is also very helpful when assessing the impression a change in a single set of requirements might have on the implementation of different necessities. Remember, in a world overflowing with information and selections, traceability presents a clear path again to the supply. Whether you’re a consumer attempting to make an informed alternative or a business attempting to stand out, traceability is the vital thing to unlocking belief and high quality.

In Section 2.3, we’ll focus on values appearing within the necessities as properly as margin and finances relationships between individual requirement values. In Section 2.4, we will talk about the issue of integration of these statements for a given entity to ensure that not considered one of the necessities in a specification for a set of entities are in mutual conflict. In addition to these relationships, there are a number of different relationships of note between requirements and between necessities and other units of knowledge.

In the method of forcing this performance requirements analysis work, we are able to include a HOOK field in the requirements analysis database with the FUNCTION_ID. To establish a condition of traceability, we need some approach to hook up requirements for one factor to requirements for different components. Downward traceability is almost always a one-to-many relationship between a requirement and people it traces to nevertheless it most often is a one-to-one relationship within the upward path.

The modified method supplies for traceability throughout the enterprise work planning and program planning processes. A key element of the added worth of MBT is the automation of bidirectional traceability between necessities and test circumstances. Bidirectional traceability is the power to determine hyperlinks between two parts of the software program improvement course of. The starting point of the MBT course of is the various functional descriptions of the examined utility, such as use instances, practical requirements, and descriptions of business processes. To be effective, necessities traceability implies that the necessities repository is structured sufficient so that every individual requirement can be uniquely recognized.

This article discusses the current state of traceability and product recollects, the results of regulation and voluntary trade requirements on traceability, what to anticipate from a traceability audit and what methods guarantee traceability. To be capable of hint the necessities successfully, it is important to succeed in the best stage of detail. This means staying affordable and not attempting to narrate every requirement with every different one, only for the sake of it. Admittedly, it could seem typically that one requirement impacts virtually all others but in addition the other method round, nearly all necessities may seem to influence this particular one.

Whether or not the hyperlinks are physically recorded and managed they nonetheless exist. For example, a developer creates a link simply by studying a design specification and using that to drive the implementation. The definition used herein pertains to all forms of products and services and is believed to offer the premise for efficient traceability (Olsen and Borit, 2013). With respect to the food sector, this approach concurs with the position just lately taken within the USA, the biggest single food importer/exporter in the world, by the Food and Drugs Administration (FDA) in its new Food Safety Modernization Act (Nachay, 2011). Based on these arguments, this examine maintains that traceability is an infrastructure that can be used by control agencies for 2 functions. The first purpose is to retrieve different data for various causes (such as validation of documentation of environmental sustainability – e.g., food miles, emissions (Olsen, 2009) – or contamination concerns).